Using CAN bus with Nvidia AGX Xavier devices

CAN is quite useful to communicate with vehicle ECUs and telemetry systems. In this section we discuss how that can be done for Jetson-AGX Xavier devices

Note: This is a Draft

CAUTION: go through the the whole document at least once before attempting implementing a full system.

Last updated: Feb/2022

Figure 1. Wiring and pin connections

1. Basic Prerequisites

- Jetson AGX-Xavier developer platform module

- Can Transceiver IC (this can be any suitable IC, we use the SN65HVD230 from TI).

- CAN utilities installed

$ sudo apt-get install -y can-utils busybox

In this example I’ve used single core PCV thin wall cables (1mm) which is standard in most automotive settings. but you can use 0.5 mm or lower based on the connector and crimp sizes. To create twisted pairs you can use a vice to hold one end of the pair and a drill to twist slowly (or hand twist of course). To verify can traffic you can use PCAN USB PRO or a Vector CAN interface or check here for some recommendations from the embedded Linux community. In the Example I’ve used a PCAN View with a PCAN USB device in a Linux machine( there is a graphical windows interface for MS Windows).

Connecting and Configuring the Nvidia Jetson AGX-Xavier

Kernel DTB

first you need to check if the CAN nodes are enabled in the kernel device tree binary that is flashed in to the device.

$ cat /proc/device-tree/mttcan\@c310000/status

Pinmux

A CAN configured Pinmux can be set in different ways.

- Update the pinmux config files pre-flashing.

- Use the graphical Jetson-IO tool

- Use a busybox devmem tool to write to hardware registers. (Changes will persist until next system boot)

Install busybox$ sudo apt install busyboxbusybox devmem <register> w <value>( you can pick the register values from Table 1 below ) e.g.$ sudo busybox devmem 0x0c303010 w 0x400 $ sudo busybox devmem 0x0c303018 w 0x458

| CAN peripheral | Controller base address | pins on board | port addr | register | value | chip conn (SN65HVD230) |

|---|---|---|---|---|---|---|

| mttcan@c310000 | 29 | can0_din | 0x0c303018 | 0x458 | R (RX) | |

| 31 | can0_dout | 0x0c303010 | 0x400 | D (TX) | ||

| mttcan@c320000 | 37 | can1_din | 0x0c303008 | 0x458 | R (RX) | |

| 33 | can1_dout | 0x0c303000 | 0x400 | D (TX) |

Loading Kernel Drivers

load all the necessary kernel drivers in the following order.

- *Note: Use

sudomode if necessary. *$ modprobe can$ modprobe can_raw$ modprobe mttcan

Network interface setup

Example to set up a 250Kbps network. with presumed acknowledgement. (suited to a test network with one or two nodes to prevent BUSHEAVY conditions)

$ sudo ip link set can0 type can bitrate 250000 presume-ack on restart-ms 2000

$ sudo ip link set can0 up

You can use the shell script below to set all the steps in one go.

you can run $ chmod +x scriptname.sh (maybe with sudo) and then ./scriptname.sh

Setting up Register values and enabling CAN

The shell script below will update registers, set up drivers and bring the can0 interface up. The same process cab be modified to activate can1.

Disabling CAN

If you want to disable CAN for debugging (e.g. prior to updating parameters) use the script below. This unloads the drives and brings the CAN down, however the registers will remain unchanged until explicitly done so.

Testing and running code

This section uses python-can with socketcan. You can install the pythin package via pip with the following command

If you are using the system-python

sudo apt install python3-wrapt

sudo apt install python3-can

pip3 install python-can

The python examples below are tested on

| python | 3.6.9 |

| python3-wrapt | 1.9.0-3 |

| python-can | 3.3.4 |

Now your python environment is ready to work with SocketCAN

Once the can drivers and the interface is up you can use commands like [cansend][CANSENND] and candump alongside potential already existing bus traffic to inject and read CAN messages. At this point you have to be aware of the clock compatibility of the participating CAN nodes or you may get various faulty BUS ERROR conditions.

Following code example and the image is from running the python script from the Jetson and capturing the outfrom from a CAN bus monitoring software (also with candump from the sending end)

bottom: CAN trace (pc with PCAN interface)

If we trace the bus with a logic analyser scope when our CAN frames are flying through it we can see the resulting waveform. (here I have probed stage between the transceiver and the Jetson CAN peripheral, there are other special tools that can go in the can L and H on the physical differential CAN BUS too). you will notice that the dominant level is the logic LOW while in idle state the bus voltages float up. Also Notice the ACK/NACK bits that represent acknowledgements (this is quite helpful as if some nodes do not see the ACK they will report errors such as BUSHEAVY conditions.)

Note: If you don’t provide a node on the bus that does not acknowledge or do not put anything other than the sending node and the tracer the acknowledge will not be present as shown above. adding instruction lines like e.g. sudo ip link set can0 type can bitrate 250000 presume-ack on restart-ms 2000 will tell the interface to cope with out and ACK and even reset the bus in case of a “crazy chatty” node.

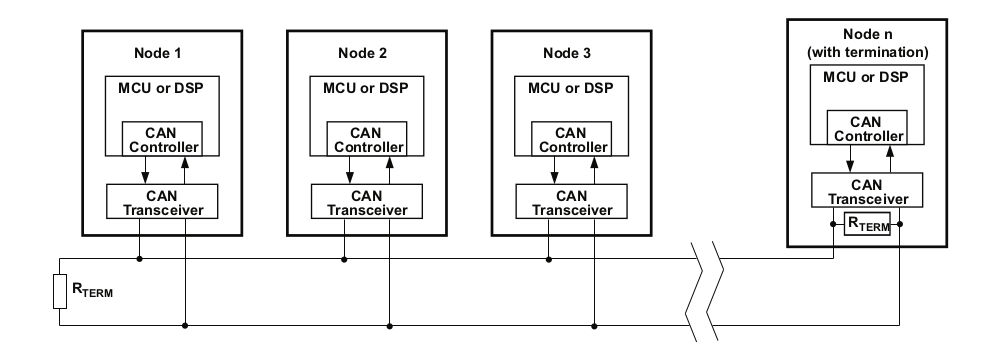

Connecting to the CAN bus.

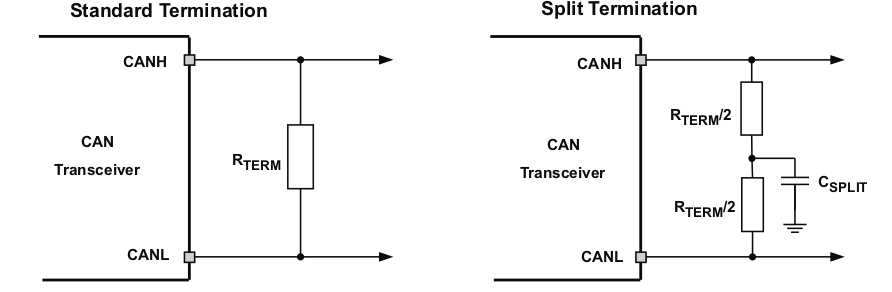

The CAN L and H from the transceiver is connected to the CAN bus as shown below. It is Important to use the right terminations at the right place to avoid reflections that may cause the bus to not perform correctly. Usually we use 120 ohm resistors in the end or in the case of a split termination (usually done in board level design)

Figure 4. CAN bus, source: datasheet

Figure 4. CAN bus, source: datasheet

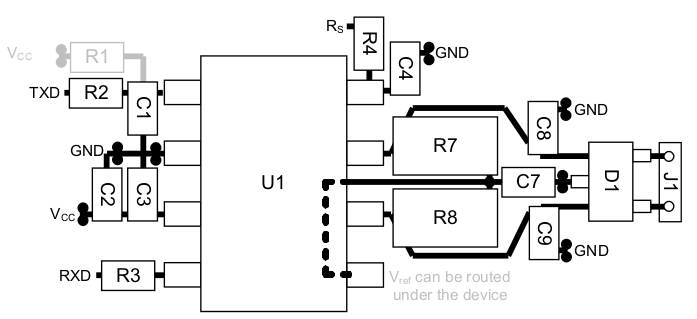

Circuit design ideas

Figure 5. PCB Can termination, source: datasheet

Figure 5. PCB Can termination, source: datasheet

PCB design ideas

Because ESD and EFT transients can be between 2Mhz and 3GHz approximately High frequency layout guidelines must be applied to the PCB design. To work in machines or vehicle plants external transient protection devices must be used at bus connectors to prevent these transients from propagating into the PCB.

- Use power and ground planes to provide low inductance paths for high frequency signals to dissipate into (rather than onto signal paths) and provide shielding.

- Design bus protection components in the direction of the signal path. (do not force transients to divert from the signal path to reach the protection device e.g. capacitor)

- It is advised to use transient voltage suppression devices (TVS) bi directional diodes or varistors and bus filter capacitors, bus transient devices should be placed close to the connector to stop them from coming in.

- You may use CAN termination on the board but however if it is used the device should be an end node and should not be removed without adding a substitute termination to the bus. (split termination provides common mode filtering from the bus)

- bypass and bulk capacitors must be placed as close to the supply pins of the transceiver.

- use at least two vias for vcc and ground connections of bypass capacitors and protection devices to minimise trace and via inductance.

- to limit current via digital lines serial resistors may be used.

- to filter noise on the digital IO lines a capacitor may be used to close the input side the IO as shown by C1 and C4.

- since the internal pull up and pull down biasing of the device is weak in the face of transients for floating pins an external 1k to 10 k pull up/down should be used to bias the state of the pin nore strongly against the noise during transient events.

- If D(TxD) is driven via an open drain/collector it should be pulled up to vcc when it is not shorted to GND through the driving gate. (look at R1)

- if the device is only operating on normal mode or slope control R£ is not needed and C4 pads can be used for the pulldown resistor to ground. if pin5 is not used it can be left floating.

Troubleshooting CAN

Setting up the physical can bus and get the electrical and software components working altogether can be challenging at times. This section is to address some of these problems in a Q&A style writeup.

CAN interface is not up

Note: (this can usually can happen with embedded platforms) (e.g. candump can0 complains that the interface is not up)

first disble CAN and try replacing sudo ip link set can0 type can bitrate 250000 presume-ack on restart-ms 2000 on the setup script with sudo ip link set can0 up type can bitrate 250000 berr-reporting on

the setup stage works fine but can’t see any messages on the bus.

This could be either an internal or external issue. first of all we need to eliminate the possibility of a failure on the jetson side (before testing external things). in order to do this we can do a loopback test.

if CAN is already set up please disable before making modifications.

at this point you can invoke the previously mentioned python script or a cansend command alongside candump (e.g. run candump can0 in a different shell)

If the jetson internals are working fine you should get something similar to what is shown below (we’ve run the script in the testing and running section )

if you get the output above and still got problems it seems that the software is running fine. However we still can’t rule out clock issues that may originate from the Jetson board that may not help with sampling issues and synchronization.

Related Nvidia Developer forum Questions

- Error due to the nodes on CAN bus having different clocks. link

Appendix

L4T 32.7.1 CAN DOCS

to change pinmux and update kernel look at $BSP/Linux_for_Tegra/kernel/pinmux/t19x/README.txt

L4T 32.7.1 IO-CONFIG-TOOL

Click here for Errors, Suggestions or Comments!